Introduction

In the ever-evolving energy and power sector, efficiency is more than just a buzzword—it’s a necessity. From wind turbines to power plants, every component plays a critical role in keeping energy systems running smoothly. One often overlooked yet essential part is the humble ball bearing. In Pakistan, the demand for energy-efficient machinery and systems is growing, and Ball Bearing Pakistan is at the forefront of providing solutions that improve the efficiency and durability of these energy systems.

This article delves into how ball bearings are pivotal in ensuring the smooth functioning of the energy and power sector in Pakistan and why choosing the right bearing can make all the difference.

The Role of Ball Bearings in Energy Systems

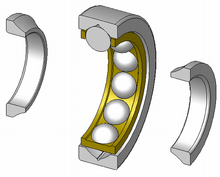

Ball bearings balls are mechanical components designed to reduce friction between rotating parts. In energy systems, where continuous operation is crucial, minimizing friction is key to maintaining efficiency and preventing wear and tear on equipment.

Why Are Ball Bearings Essential for Energy Efficiency?

Energy systems rely on rotating components to generate and distribute power. Bearings enable these components to rotate smoothly by reducing friction, heat, and energy loss. Without the right ball bearing, machinery would face higher friction, leading to inefficiencies, overheating, and potential breakdowns.

By reducing resistance, Ball Bearing Pakistan helps ensure that energy systems operate at peak performance with minimal energy waste.

Types of Ball Bearings Used in the Energy Sector

Different applications in the energy and power sector require specific types of ball bearings. The choice of bearing depends on factors like load capacity, speed, and environmental conditions.

1. Deep Groove Ball Bearings

Deep groove ball bearings are widely used in power plants and renewable energy applications like wind turbines. These bearings are highly durable and capable of handling both radial and axial loads, making them a versatile choice for energy systems.

2. Spherical Roller Bearings

In large energy applications, such as turbines and generators, spherical roller bearings are preferred for their ability to handle high loads and misalignment. These bearings are designed to withstand harsh operating conditions, making them ideal for heavy-duty energy machinery.

3. Ceramic Ball Bearings

Ceramic ball bearings are commonly used in high-speed energy applications. They are lightweight, have excellent thermal resistance, and produce less friction compared to steel bearings. This makes them ideal for industries that require high efficiency and longevity, such as the solar and wind energy sectors.

Ball Bearings and Renewable Energy

The renewable energy sector is expanding rapidly in Pakistan, with a focus on reducing carbon emissions and improving energy efficiency. Ball bearings play a crucial role in ensuring the success of renewable energy projects, particularly in wind turbines and solar energy systems.

Wind Turbines and Ball Bearings

Wind turbines rely on a variety of rotating components, and the efficiency of these turbines depends on the quality of the bearings used. Ball Bearing Pakistan supplies high-quality bearings that can withstand the high axial and radial loads exerted by wind turbine blades. Bearings in wind turbines also need to resist extreme environmental conditions, including moisture, dirt, and temperature fluctuations.

By minimizing friction and ensuring smooth rotation, the right ball bearings help maximize energy production from wind turbines.

Solar Energy and Ball Bearings

In solar power systems, ball bearings are used in tracking mechanisms that allow solar panels to follow the sun’s path throughout the day. This movement increases the efficiency of solar energy capture. The bearings in these systems need to be lightweight, low-maintenance, and capable of withstanding outdoor elements, making ceramic ball bearings a popular choice.

Energy Efficiency and Cost Savings

In energy and power sectors, efficiency directly translates to cost savings. Equipment that operates with lower friction and reduced energy loss ultimately leads to lower operational costs. Bearings designed for energy systems are engineered to provide maximum efficiency, reducing the overall energy consumption of machinery.

Reducing Downtime with High-Quality Ball Bearings

In energy production, downtime is a major concern. Every minute that machinery isn’t operating leads to lost energy production and increased costs. By choosing the right Ball Bearing Pakistan, energy companies can reduce the frequency of breakdowns and extend the operational life of their equipment.

Maintenance and Longevity

Proper maintenance of ball bearings is essential to ensure the longevity of energy systems. Regular lubrication and inspections can prevent premature bearing failure. High-quality bearings from Ball Bearing Pakistan are designed for durability, reducing the need for frequent maintenance and replacement.

Environmental Considerations

With the global push towards sustainability, energy companies in Pakistan are looking for ways to reduce their environmental impact. Ball bearings contribute to these efforts by enhancing energy efficiency, reducing emissions, and minimizing waste.

Sustainable Manufacturing of Ball Bearings

Manufacturers of Ball Bearing Pakistan are increasingly focusing on sustainable production methods. This includes using recyclable materials, reducing energy consumption during manufacturing, and producing longer-lasting bearings that reduce the need for frequent replacements.

Energy Efficiency and Carbon Footprint

Ball bearings designed for energy efficiency contribute to a lower carbon footprint by reducing the energy required to run machinery. In industries like wind and solar power, where the goal is to reduce reliance on fossil fuels, energy-efficient ball bearings play a crucial role in achieving sustainability targets.

Choosing the Right Ball Bearing for Your Energy Needs

Selecting the appropriate ball bearing for your specific energy application can be challenging, but it’s essential for optimizing efficiency and reducing costs. Here’s what to consider:

1. Load Capacity

Different energy applications have varying load requirements. For example, wind turbines experience high axial and radial loads, while solar tracking systems require bearings that can handle light, continuous movement. Understanding the load capacity of your machinery is the first step in choosing the right bearing.

2. Operating Environment

Energy systems often operate in harsh conditions, from high temperatures to moisture and dirt exposure. Bearings must be designed to withstand these conditions without degrading in performance.

3. Speed Requirements

In high-speed applications, such as those found in some power generation systems, bearings need to handle rapid rotation without generating excess heat or friction. Ceramic ball bearings are often used in these situations for their superior speed capabilities.

4. Material Durability

Materials like stainless steel and ceramic are commonly used in energy sector bearings due to their durability and resistance to corrosion. Selecting the right material for your bearing ensures it will last longer and perform efficiently.

Conclusion

Ball bearings may be small, but they have a massive impact on the efficiency and reliability of energy and power systems in Pakistan. From renewable energy projects to traditional power plants, the role of ball bearings cannot be overstated. By choosing high-quality, durable, and efficient ball bearings from Ball Bearing Pakistan, companies can enhance their energy production, reduce costs, and contribute to a more sustainable future.

The energy and power sector’s reliance on ball bearings will only grow as technology advances and sustainability becomes a priority. Making the right choices today will ensure the success and longevity of your energy systems for years to come.

FAQs

1. How do ball bearings improve energy efficiency?

Ball bearings reduce friction between rotating parts, allowing machinery to operate more smoothly and with less energy loss, improving overall efficiency.

2. Which ball bearings are used in wind turbines?

Wind turbines typically use deep groove ball bearings and spherical roller bearings due to their ability to handle high loads and resist harsh environmental conditions.

3. What makes ceramic ball bearings a good choice for solar power systems?

Ceramic ball bearings are lightweight, resistant to heat, and produce less friction, making them ideal for solar power systems that require precise and efficient tracking.

4. How does reducing friction in energy systems save costs?

By reducing friction, ball bearings help machinery run more efficiently, which reduces energy consumption and lowers operational costs.

5. Are ball bearings important for renewable energy systems?

Yes, ball bearings are crucial for the efficient operation of renewable energy systems like wind and solar power. They help ensure that rotating components operate smoothly, enhancing energy production.

For more information: SBS Bearings