When working with RF (radio frequency) components, choosing the right submount and carrier is critical. These components play a major role in ensuring that your devices work effectively. If you’re involved in industries like telecommunications, radar systems, or electronics, understanding how to select the proper submount and carrier can save you time, money, and technical headaches.

But don’t worry—this article is designed to make the process simple and easy to understand, even if you’re not a technical expert. We will walk you through the basics, cover what to consider when making your decision, and provide some real-world examples that can help guide your choice.

Let’s dive in!

What Is an RF Submount and Carrier?

Before we get into how to choose the right submount and carrier, it’s essential to understand what these components are.

- RF Submount

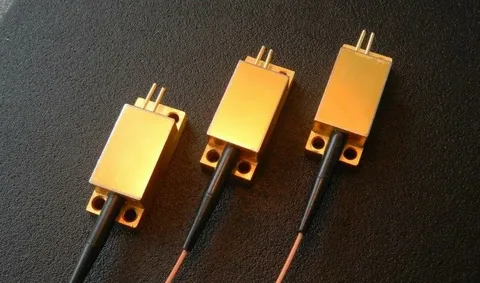

This is a base or platform on which RF components, such as diodes or chips, are mounted. It acts as the foundation, ensuring that the component stays in place and performs optimally. Submounts can help with heat management, electrical connectivity, and overall stability.

- RF Carrier

The carrier is like the “housing” for the submount and other RF components. It protects the submount from external damage and helps ensure efficient communication of radio frequencies. Carriers also assist with heat dissipation and can improve the reliability of the device over time.

Why Is Choosing the Right RF Submount and Carrier Important?

Choosing the correct submount and carrier for your RF application ensures your device will function efficiently, safely, and for a long time. A poor choice can lead to overheating, electrical malfunctions, or reduced signal quality.

When you select the proper submount and carrier, you optimize the performance of your RF device, ensuring that it handles stress, heat, and other factors effectively.

Factors to Consider When Choosing RF Submounts and Carriers:

Now that we’ve covered the basics, let’s get into the specifics of how to choose the right RF Submounts and Carriers. There are several factors you need to consider to make the right decision.

1. Material

The material of the submount and carrier is one of the most important factors. Common materials include:

- Ceramic:

Ceramic is a popular choice for submounts because it is durable, heat-resistant, and offers good electrical insulation. It’s often used in high-frequency applications. - Metal:

Metal carriers are used for their strength and ability to conduct heat. Metals like copper or aluminum are often chosen because they provide excellent thermal conductivity, helping to dissipate heat quickly. - Silicon:

Silicon submounts are used when miniaturization is needed. Silicon has excellent thermal properties, and it’s a good choice for compact RF applications.

Tip: Make sure the material you choose suits the operating environment. For example, if the device will be exposed to high temperatures, choose materials with good heat resistance like ceramic or metal.

2. Thermal Management

Heat dissipation is a crucial factor in RF applications. Poor thermal management can lead to overheating, damaging your components and reducing the lifespan of your device. Both the submount and the carrier need to work together to ensure proper heat management.

What to Look For:

- Thermal Conductivity:

The material should have good thermal conductivity, allowing heat to move away from sensitive areas. - Heat Sinks:

Some carriers come with built-in heat sinks to help with heat dissipation. Consider this feature if your application involves high power.

3. Electrical Performance

The submount and carrier need to ensure proper electrical performance, meaning they should have excellent electrical insulation while allowing the RF signals to pass through without interference.

Things to Keep in Mind:

- Insulation:

Make sure the submount provides adequate electrical insulation, especially if you are working with high voltages or power levels. - Signal Integrity:

The carrier should maintain signal integrity. Some materials can cause interference, so choose a material that minimizes signal loss.

4. Size and Shape

The size and shape of the RF submount and carrier should match your specific application. These components must fit well into your device to avoid loose connections or inefficient performance.

Here’s what to consider:

- Compatibility:

Check that the submount and carrier are compatible with the rest of your RF components. Look at the dimensions and ensure everything will fit properly in the final design. - Miniaturization:

Some modern applications require very small RF devices. If miniaturization is important, choose a submount and carrier that are compact but still offer good performance.

5. Environmental Factors

The environment in which the RF device will be used plays a key role in selecting the right submount and carrier. If the device will be exposed to extreme temperatures, moisture, or vibration, you need to choose components that can withstand those conditions.

For example:

- High-Temperature Environments:

If your device will be operating in a high-temperature environment, make sure to choose materials that won’t degrade under extreme heat. - Outdoor Use:

For outdoor applications, look for submounts and carriers that are moisture-resistant and able to handle temperature fluctuations.

6. Cost and Availability

While it’s important to select the best possible components for your RF application, you should also consider your budget and the availability of materials.

Tips for balancing cost and performance:

- Set a Budget:

Determine how much you’re willing to spend on the submount and carrier. While premium materials may offer better performance, they might not always be necessary for every application. - Check Lead Times:

Some specialized materials or components may have long lead times. Plan accordingly, especially if you are working on a tight deadline.

Conclusion

Selecting the right RF Submounts and Carriers is critical for ensuring the performance and longevity of your RF device. By considering factors such as material, thermal management, electrical performance, size, environmental conditions, and cost, you can make an informed choice that meets the needs of your specific application. Thank visiting nytimer.uk