Falling film evaporators are vital components in various industrial processes, particularly in the food and beverage, chemical, and pharmaceutical industries. They help to concentrate solutions efficiently by evaporating water or other solvents, using a thin film of liquid that flows down vertical heat exchanger surfaces.

So, if you’re new to operating a falling film evaporator or need a refresher, this guide will walk you through the essentials of operating these systems effectively and safely.

Understanding the Basics

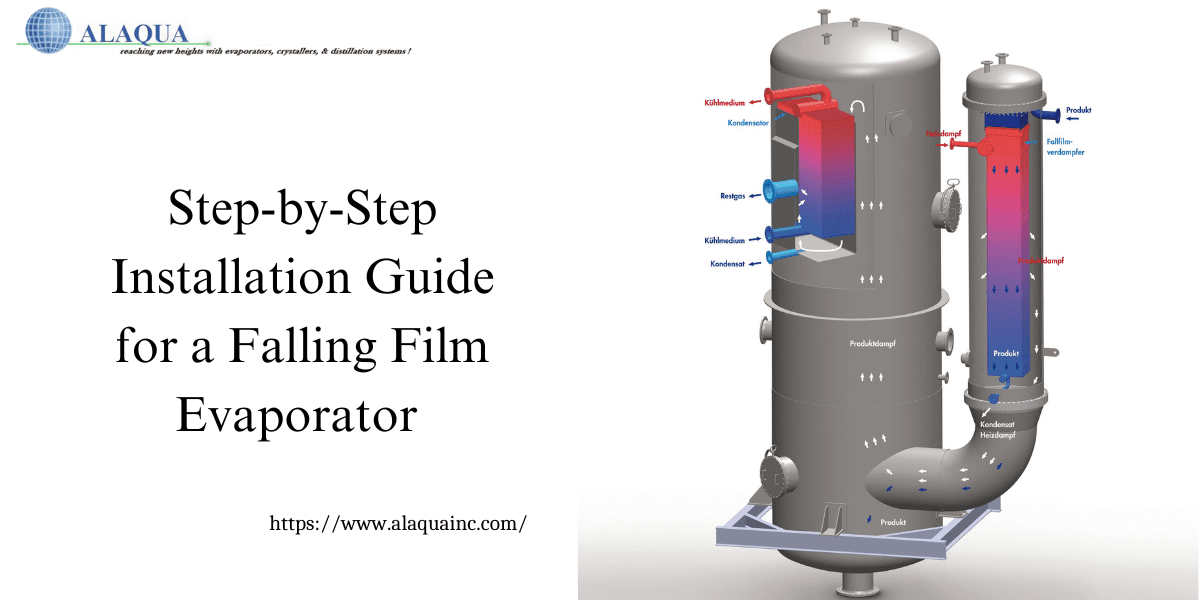

A falling film evaporator consists of a vertical cylinder with multiple heat exchange tubes. The process starts with a feed solution being distributed at the top of the evaporator. The liquid then uses gravity to move in a thin coating along the inside of the tubes. As the liquid flows down, heat is applied to the outside of the tubes, causing the solvent to evaporate. Further, the resulting concentrated liquid exits the evaporator, while the evaporated solvent is collected separately.

Steps Involved in the Operating of Falling Film Evaporator

Step-by-step guide for operating the evaporator:-

Pre-Operation Checks

Before operating a falling film evaporator, it’s crucial to perform several pre-operation checks to ensure the system runs smoothly:

- Inspect Equipment: Check for any visible signs of wear, leaks, or damage. Ensure that all components, including the feed pump, heat exchanger, and condensate removal system, are in good working order.

- Verify Connections: Confirm that all pipes, valves, and electrical connections are secure. Look for any potential sources of leaks.

- Clean the System: If the evaporator has been idle, clean the system thoroughly to remove any residual materials or contaminants. This step helps in preventing cross-contamination and ensures efficient operation.

Setting Up the Feed Solution

The feed solution is the liquid mixture you wish to concentrate. Proper preparation of this solution is essential for optimal performance:

- Prepare the Solution: Ensure the feed solution is mixed according to the desired concentration. It should be homogeneous to prevent clogging or uneven distribution.

- Adjust Temperature and Flow Rate: Set the feed solution to the appropriate temperature and flow rate. So, consult the evaporator’s manual for specific guidelines related to your system’s design.

Operating the Evaporator

Once the pre-operation checks are complete and the feed solution is ready, follow these steps to operate the falling film evaporator:

- Start the System: Turn on the main power supply and activate the control panel. Check to make sure each indicator is performing as it should.

- Feed Solution Introduction: Begin feeding the solution into the evaporator. Adjust the feed rate to match the specifications outlined in the evaporator’s manual. Moreover, an accurate feed rate helps maintain the proper film thickness and ensures efficient evaporation.

- Heat Application: Set the heat source to the required temperature. The heat is typically provided by steam or another heating medium. Also, monitor the temperature closely to avoid overheating or underheating, which can affect the evaporation process.

- Monitor the Process: Keep a close eye on the evaporator’s performance metrics, such as temperature, pressure, and flow rates. Regular monitoring helps detect any issues early and allows for adjustments to optimise efficiency.

Handling the Concentrate and Vapour

As the evaporation process progresses, you’ll need to manage the concentrated liquid and the evaporated vapour:

- Concentrated Liquid: The concentrated liquid exits the evaporator from the bottom. Collect it in a designated container and ensure it is appropriately processed or stored according to your operational requirements.

- Vapor Collection: The vapor generated during the process is usually collected and condensed into a separate liquid phase. Ensure that the vapor handling system, including the condenser, is functioning correctly to avoid any loss of valuable solvent.

Safety Measures

Operating a falling film evaporator involves handling high temperatures and pressures, so safety is paramount:

- Protective Gear: Always wear appropriate protective gear, including gloves, goggles, and lab coats, to protect yourself from potential hazards.

- Emergency Procedures: Familiarize yourself with emergency shutdown procedures and ensure that all safety systems, such as alarms and pressure relief valves, are operational.

- Training: Ensure that all operators are adequately trained and understand the potential risks associated with falling film evaporators. Appropriate training increases overall productivity and lowers the risk of accidents.

Post-Operation Procedures

After completing a processing run, follow these post-operation procedures to maintain the system and prepare it for the next use:

- Shutdown: Gradually reduce the heat and stop the feed solution. Let the system cool down completely before doing any repairs.

- Clean the System: Perform a thorough cleaning of the evaporator to remove any residual materials. Use appropriate cleaning agents and follow manufacturer recommendations for cleaning procedures.

- Inspect and Maintain: Examine the equipment one last time. Look for any signs of wear or damage and perform any necessary maintenance or repairs.

Troubleshooting Common Issues

Even with careful operation, issues may arise. Below is a list of frequent issues along with their fixes:

- Scaling or Fouling: Scaling on the heat exchange surfaces can reduce efficiency. Regularly clean the system and consider using anti-scaling agents if needed.

- Inconsistent Concentration: If the concentration of the final product is inconsistent, check the feed solution’s homogeneity and adjust the feed rate or heat settings as necessary.

- Leaks: If you notice leaks, check all connections and seals. Tighten or replace any damaged components as needed.

Final Thoughts

Operating a falling film evaporator efficiently requires a combination of proper setup, careful monitoring, and adherence to safety protocols. By understanding the basics of falling film evaporator working principle, performing thorough pre-operation checks, and following best practices during operation and maintenance, you can ensure that your evaporator runs smoothly and effectively. Regular training and vigilance will help you manage the system effectively and address any issues that arise, ensuring the success of your evaporation processes.